Archive

Morley Bar Stool – Make another seat

When last we visited the seat construction was going well and i was going to finish the blog with a quick view into cutting the seat to final dimensions. That did not go as planned so I got to make one more seat blank and repeat!

Here’s what happened and several lessons that followed. The blanks needed to be smoothed and I did this using a belt sander for their concave curves and I hand plane and sander for the convex curves. Yeah I know the hand tools keep sneaking into the process. No pictures of the smoothing but I think you can imagine it. Once the curve was smooth the seat blank (curved needed to be trimmed to size and shaped. You can see the template in the picture below.

I mounted the template onto the first three blanks and trimmed it on the bandsaw and used the router table to bring out to final shape. Blank number three…Don’t tell anyone but I screwed the template on in the wrong direction! The bandsaw was very efficient as it cut off the wrong end and I had a seat without enough depth…firewood! I took the other blanks and all went well until the last one where the router ate part of the blank. Puzzled I learned that the router bit was too low since the mounting bolt had loosened. Two mistakes and I leave the shop. No sense i risking injuries when I am frustrated with myself.

Later I returned to the lumber yard picked up a new board and made two more seat blanks. This also brought about a new lesson, I could not cut the curve smoothly on the blank. After several minutes I remembered changing to the wider bandsaw blade and realized that it was preventing the blade to match the desired curve. As I mention I am relatively new to the bandsaw and curved jigs. A narrower blade and everything worked well.

Jig Building – Morley Bar Stools

There are four stools to be made as part of this project and repetitive tasks lend themselves to power tools and jigs. Not being a frequent jig builder, I found this a challenge and in particular the instructions were not as clear as I hoped. I’ll share a few photos and a brief description of the method I came up with after watching the videos of the jigs in action.

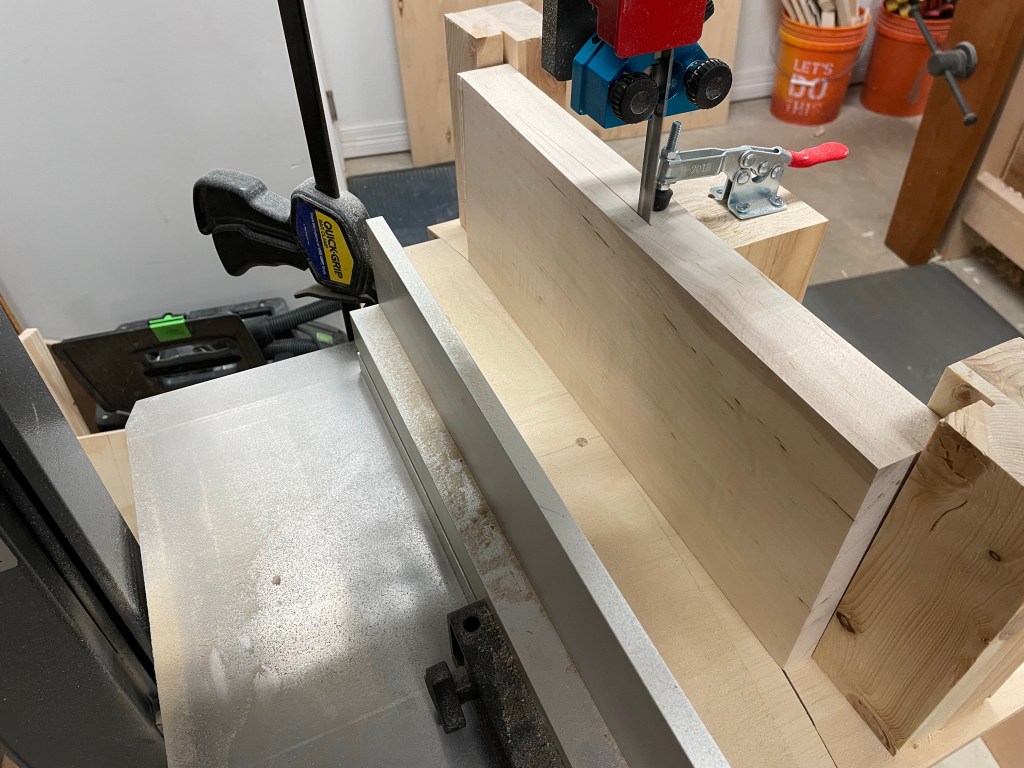

The seat consists of three boards with a curved front and back. Each curve requires a separate jig. Let’s take a look at the concave cut first

The Jig consists of two curves made of plywood. One piece fixed to the band saw with a clamp and a second that rides alongt the edge of the first piece of plywood like a turn table. On these pieces I glued up a couple of pieces of 2×4 to ma end support structure for the seat blanks and a third that will allow a clamp to be placed to hold the blank secure. The two support strucures required a couple of cuts on the table saw to securely first the blank at the correct angle

In the pictures below you can see how the two pieces of plywood interact.

I think you can scroll through the pictures and see that the second jig is similar to the first but I placed the saw on the inside of the clamped pieces at the interaction of the two curves.

Morley Bar Stool Leg Repair

After the incident with the router leg template, things went fairly well with the exception of tear out on another leg. Managed to catch the grain and took a corner off one of the legs. Since it was close to the edge I made a repair before rerouting to salvage the lumber.

Digging through the scraps, I found a suitable piece of lumber that has similar grain and prepared a replacement piece to fit into the damaged area. Glued it in place and planed it flat and you can hardly tell there was a problem. Now I need to be careful to place the repair on the inside of the leg and no one will know.

Hopefully I can confine the lessons and mistakes to the one stool and in the end probably reproduce another.

Morley Bar Stool – Legs

Getting the grain right on the legs is critical for both strength and appearance. I spent quite a lot of time with templates selecting which pieces to use and which to avoid. The lumber was then cut and dimensioned with the usual power tools. Finally I used the bandsaw to get close to the final dimensions and then it was on to the router and template. Very new techniques for me.

Using a guided bit and template I made the plywood jig then fastened on clamps and everything seemed to work well.

Until it didn’t….while finishing the third leg one of the clamp supports came loose and the router decided to make its own path. A few screws to repair the jig and a new piece of lumber were needed to complete the legs for all four stools.

Morley Bar Stool Seat

The original stool design has contrasting lumber for the legs and seat. its a design that I like and with the legs cherry, it made sense to go with a lighter colored maple for the seat. The seat design requires three pieces of lumber to be glued together followed by shaping on the band saw. The shaping jigs will be an entirely new process so let’s get moving!

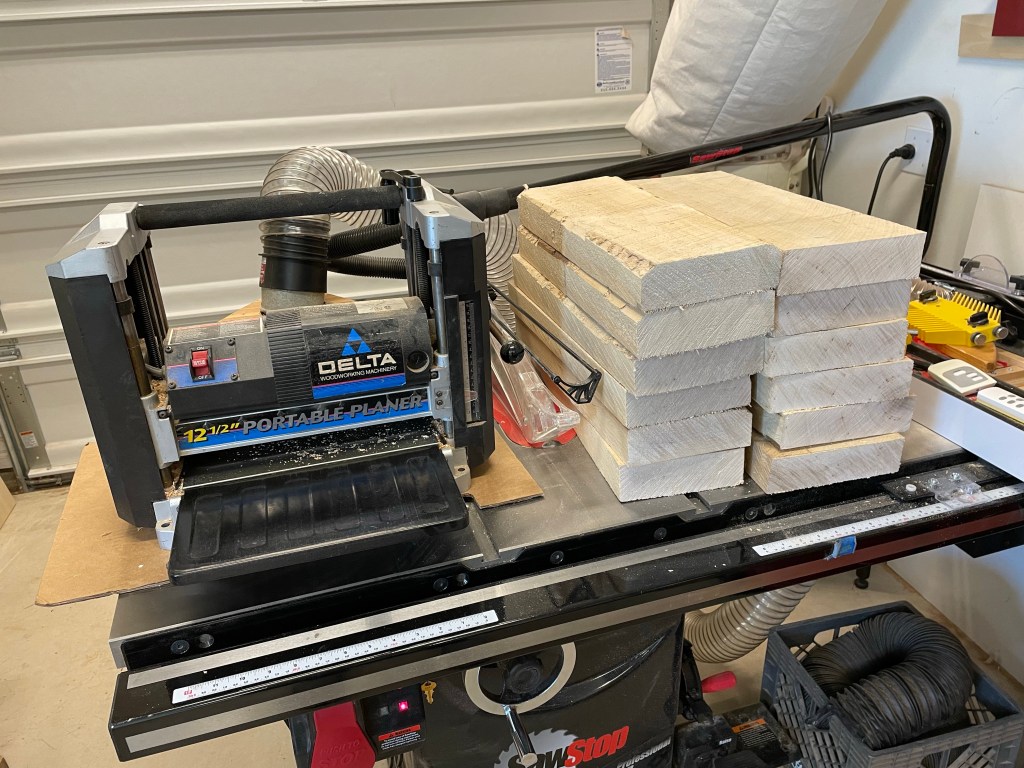

I used the usual methods for prepping the lumber to make the seat blanks. Handsaw to cut to length and then the planer to flatten the sides. Nothing unique from my other projects. Once the pieces were milled and edges square it was time for building jigs.

Along the way I did make a modification to my planer. I never purchased the attachment for dust collection (wish I had, but its now unavailable) and have been using a homemade attachment for many years. I finally swapped out the flange for attaching the dust hose and it is a much needed improvement.

The jigs for curving the seat were relatively straight forward (I did very well on the leg jig) It’s really a piece of plywood that is trimmed to fit the curve. One piece rides inside the other on the bandsaw and with a few clamps its done.

The only issue I had was a broken bandsaw blade which looks like a manufacturing defect.

Blanks were glued and clamped and the seats are 50% complete. All it needs is some shaping and trimming.

Morley Bar Stool Lumber

After downloading plans from the Wood Whisperer Guild I thought hard about the lumber in my shop what wood I would prefer to work with and what my ‘customers’ would like. There is some very nice Walnut that I have for another project that I looked at very seriously but the dimensions did not lend themselves well and the amount of waste a little concerning.

I decided to use maple for the seat and cherry for the structure. Since I didn’t consult my clients they readily agreed. Hopefully the maple and cherry will work well together. The lumber yard I use here in San Antonio has worked out well, they have a unique system, commented on a few months ago. I was very surprised at the cost of the Cherry, pleasantly surprised! Once it was in the shop I didn’t waste time cutting it into smaller pieces. My shop works fine but the 10’ lengths of lumber are quite a tripping hazard.

Starting with the Maple I crosscut it to lengths and began milling it into blanks for milling and shaping. I admit that the virus certainly took a little bit of my breath away but it felt very good to cut these by hand and I couldn’t have asked for a better saw. If you haven’t visited Bad Axe Saws lately they appear to be doing well and as they move through a change in ownership Mark Harrell is still next door and providing teaching and saw sharpening through his new company sawsharp. You can find him on instagram at SawSharp6. BTW I recommend his saws because of the excellent quality and service he has provided me over the years and have no financial or other relationship with or Bad Axe Toolworks.

The design of the seats will require a couple of jigs and the bandsaw as I move into the power tools.