Archive

Kitchen Guitar Stool -Legs

Stools are fairly simple structures. Legs, aprons, cross braces, and seats. The challenge comes when making them strong and stable, adding angles to joints. The design that Becksvoort developed uses mortise and tenon joints for the aprons and tapered rungs fitted into tenons to provide cross braces. His choice of tapered rungs makes great sense. They are simple to make and using an angled hole is quicker and simpler than using a square mortise. Additionally, the rungs will not show the wear of square braces. Since I don’t have a lathe, I will be making angled mortises and tenons.

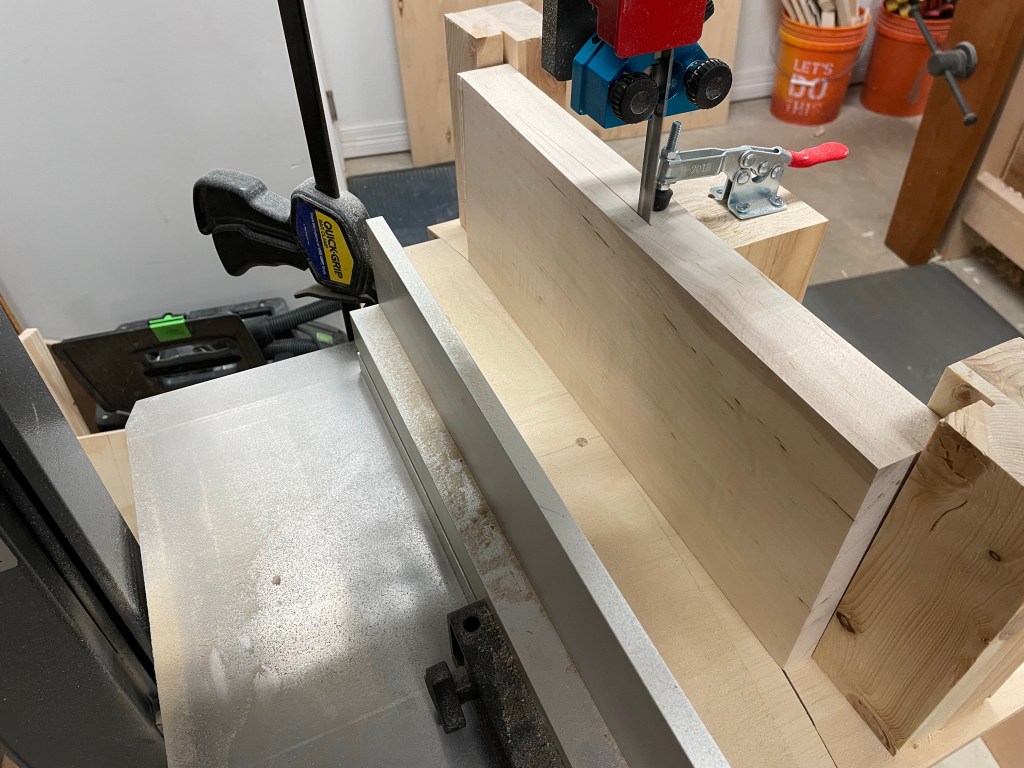

After dimensioning the legs the apron mortises were cut using my powered mortiser (love this machine) The great thing about Becksvoort’s Apron design is that the apron tenons are angled allowing the mortises to be straight.

Now for the aprons and tenons to fit into these mortises. Angled legs create great challenges and the use of straight mortises means that the Aprons must have angled tenons.

Length was made on the Tablesaw using my mitre sled followed by cutting the tenon by hand. There’s many ways to cut the tenon and as an afterthought probably some more accurate methods, but getting out the hand saw was quick and I need the saw to adjust the width anyway.

Lastly I cut them at a 45 degree angle. It’s a simple pleasure to make the cut.

As a larger challenge the plans called for the angles to be different for each side. Don’t tell anyone but I ignored the two degree difference. I’ll see at the end if this was a mistake.

Self proposed challenges. The little things that didn’t go quite as planned. The precise cutting of the tenons was enhanced by miscutting the length not once but twice. this left the mortises slightly long. Not a big problem just required a small piece to infill the mortise. There was also the problem with the runaway drill. We all do multiple projects and I accidentally used the leg as a backstop for drilling a hole. Since this is a piece for my own use I just plugged the hole and moved on.

Kitchen – Guitar Stool – Dimensioning Lumber

Slow start today. Running this morning in almost 80 percent humidity took the ‘get up and go’ out of me so it was mid afternoon before I wandered into the shop. Continuing to contemplate wood choice I finally just dove in with the cherry left over from prior projects. It’s a bit of a mixture of sizes and it took a bit of sorting before I had the major components identified.

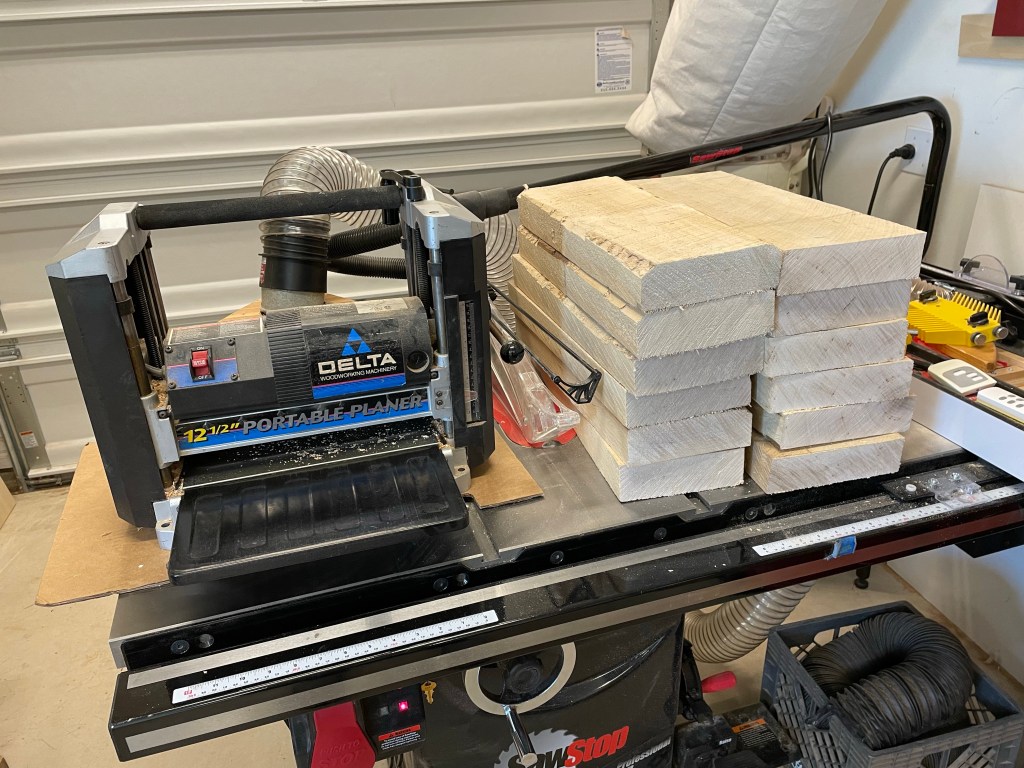

Then it was table saw, bandsaw and planer until the legs were the same dimensions and square and the upper rails all the correct width and size.

I did take the time to ensure that all surfaces were flat before cutting the larger board to make the upper rails, used my planer as a jointer per the usual process.

Sometimes you’ve just got to make a decision and move forward. One little bit of risk I had to consider was that the width of one of the legs was just under size. I could make them all slightly smaller …or I could make sure that the edge is tapered and hope that I don’t taper the wrong side. You can clearly see the leg that needs to be watched in the picture below.

Thinking ahead, the seat of the stool in the article is made of leather and since She who works Leather and Wood is not nearby (Please visit Marilyn’s blog). I’ll have to find an alternate place to get some help. There’s a little shop that I pass occasionally maybe I’ll stop in and see if they can do the seat.

Cherry Side Table Joinery

The title mentions joinery, on this page I have now mentioned joinery three times. The pictures lead you to think that perhaps there will be many joinery photographs, however someone was more focused on cutting the joints than photographing them.

There is little new woodworking on this project. It is similar to the prior Walnut side table and the through tenons require precise measurement and chisel work. These joints were mostly cut by hand, after all cherry is a pleasure to work and the rhythmic chopping is the calm after a storm.

A couple of problems occurred while make the joints and I think this picture shows them all. The first occurred while dry fitting the saddle joint in the upper cross pieces. Although the joint fit fine the small amount of pressure when asssembling resulted in a crack along the grain. The upper right of the photograph shows this piece clamped. The second thing to notice is the organized chaos. While glueing the broken joint, I worked on several pieces to save time. What did not reveal itself until glue up was that I had planed all the pieces removing many of the marking and numbers. This suddenly revealed itself in the glue up when the LAST PIECE did not fit well!

The result of this misfit was a minor wobble when the table was glued together. This was easy to fix by planing the bottom of one leg. I sharpened up the #4 and right before the first swipe realized that a little care may save me from breaking a corner. I carefully clamped a couple of pieces of scrap to the back end and took about three strokes and the wobble was gone.

The only thing left was to screw the top and bottom together and add a couple of coats of Shellac.

Several lessons from this piece: Repeating a project provides the chance to modify and change certain aspects. In this case the edge of the top was chamfered and the joints varied. More attention to wood grain adds to the appeal. Finishing is still a problem, but by using a rag rather then a brush it was much improved. Number your parts where you won’t remove the marks. High Angle frogs make a difference.

Cherry Side Table Top

Wanting to get the glue up of the top out of the way and move onto the joinery, I spent quite a bit of time flipping boards and matching grain. When the finish goes on we will see how it looks.

Here’s a link to my method for dimensioning stock, dimensioning without a jointer. Jointing the edges, I used my #7 plane which was really overkill. the bed length really helps to create flat edges but I could have accomplished the task with a #5 or #4. I just happen to like the #7.

In the last few projects I could have done a better job gluing the top. Aligning all of the boards has been a challenge which creates more work to prepare the top after glue up. I took a little more time and care to ensure alignment when clamping and there was definitely improvement. I suppose that I could use biscuits or dowels to help but I’ve not done that in over 10 years. I think it is something that with increased awareness will improve.

When the clamps were removed, there was a small amount of misalignment but much improved. I used two planes to smooth the top and with the tight reversing grain I was glad to have the Lie Nielsen #4 with a high angled frog. I’ll write a separate blog about why I have this plane in the near future.